Component : Aluminum Front Crash System

- A new crash beam&box is designed with the 6XXX aluminium series to comply with the homologative targets of CO2 emission.

- With this study crash system weight is decreased from 7,4 kg to 4,6 kg

- Gained 2,8kg weight reduction with the cost optimisation target which is -1kg ≤ 4€/vehicle

Techical details and lessons learned ;

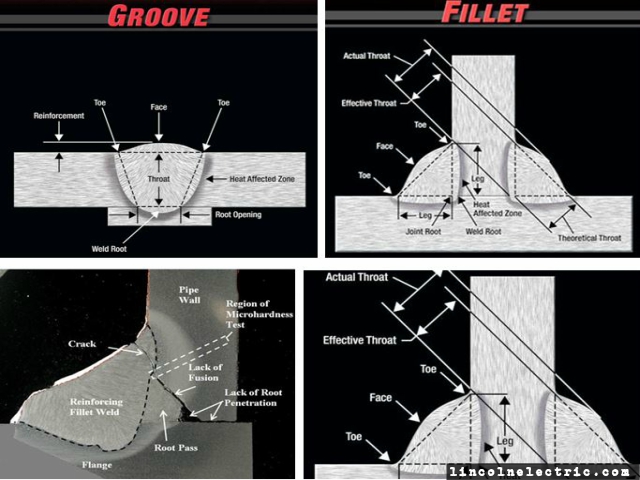

- Optimised beam and box sections to comply with pendulum verifications, low&high velocity impact tests with 40-100 % overlap etc.

- Crushing verification of box structure during crash scenario.

- Galvanic corrosion protection methods between beam and body structure

- Natural and artificial agening characteristics of Al parts and their effect on Product

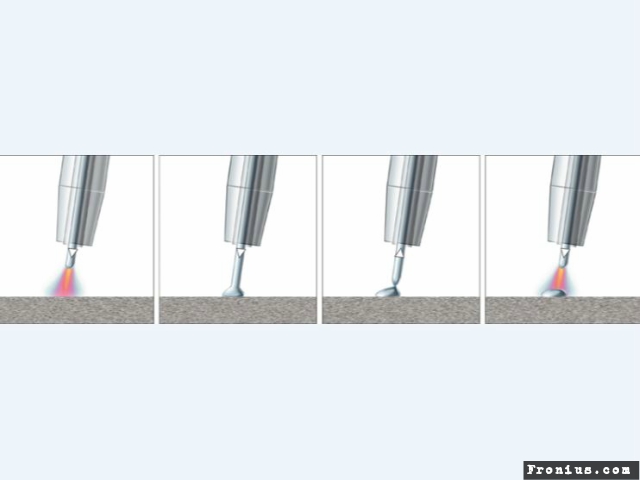

- CMT(cold metal transfer) welding, welding wire selection, welding parameters